-

- Posts: 2

- Joined: Wed May 10, 2017 12:48 am

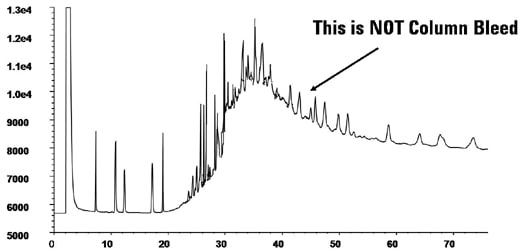

Im having issues with my baseline when running aqueous samples. My aqueous media contains a series of organics (for microbial degradation) as well as dissolved minerals. Prior to injection the solution is centrifuged then passed through a 0.2 micron pore size syringe filter. My baseline starts off at zero and fluctuations lightly between 0 and 30 microvolts. However, upon temperature ramp my baseline increases to over 300. Additionally, I am seeing peaks of my specific analytes (previously determined elution time) shift and they are also being distorted.

My specs are:

Varian 450 GC-FID

Helium carrier

flow rate - 2.5 ml/min

injector temp 300

Oven ramp - 35C (start) hold for 2 min (at two min mark is when drift occurs)

ramp @ 40C/min to 175C, hold for 1 min

FID temp = 300C

column = VF-5ms

Any help would be appreciated. I've posted an example photo (i took from online - not mine) which shows the trend, however there are sometimes discrete peaks when running an actual sample and when running pure reverse osmosis water, there are not.