-

- Posts: 184

- Joined: Sun Oct 04, 2009 6:18 pm

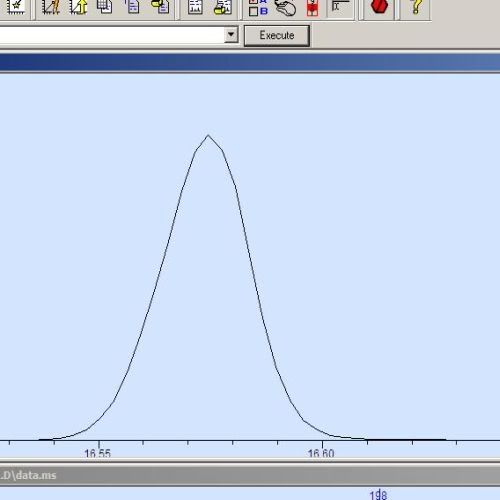

I am using a multi-baffled liner with no wool, 2x5uL injections with a 3second delay between injections, solvent flush (hexane) @ 40mL/min, inlet initial temp 30C. Months ago this very same method proved successful for another analyst in charge of the instrument. I just can't see what might be wrong. There must be something very very wrong with the system, and I'm so new to the gerstel PTV it could be something so simple...I hope it is, and I hope I discover it. There's only ONE thing I found in literature that could account for the peak-splitting I'm seeing, and that's a small amount of liquid hexane making it's way to the head of the column..but if this is the case..what could have changed?? I am now testing this morning with a small amount of wool in the liner to see if this improves..or just CHANGES anything..

Christian