-

- Posts: 31

- Joined: Tue Oct 21, 2008 2:26 pm

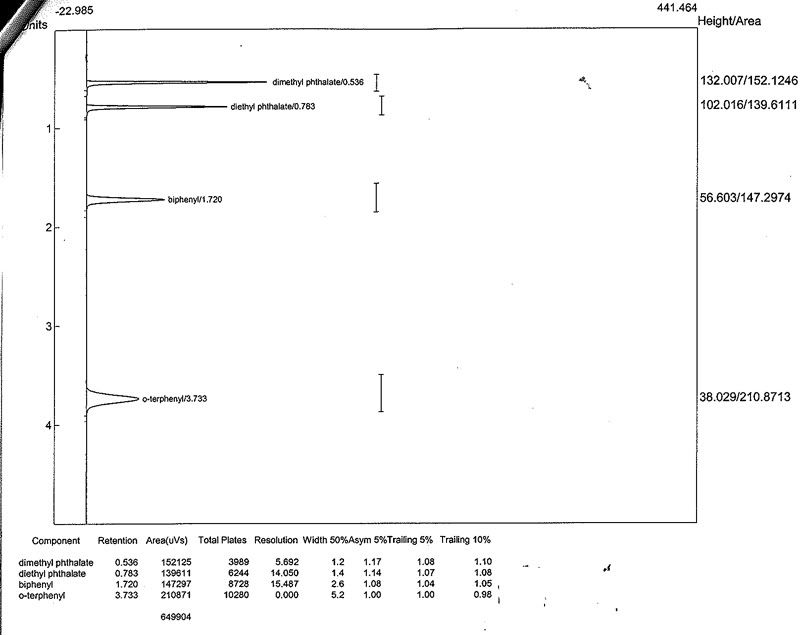

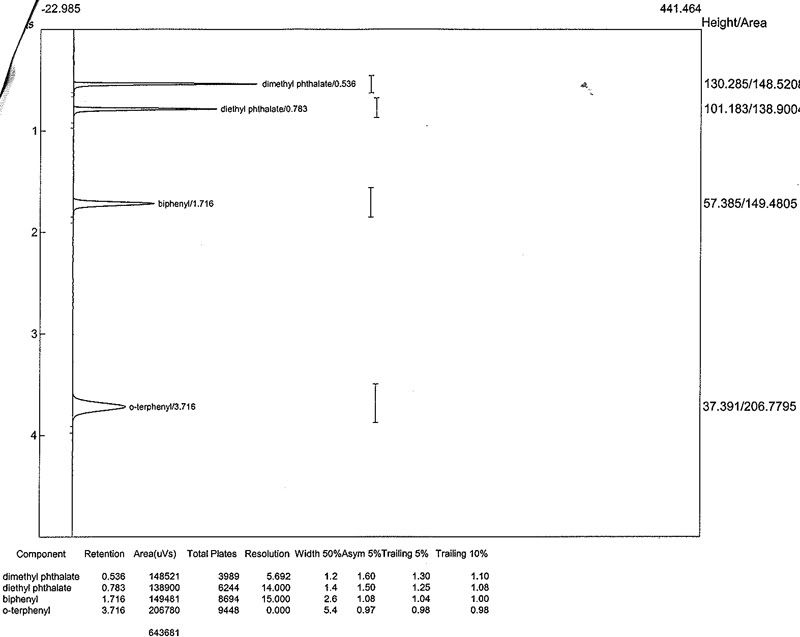

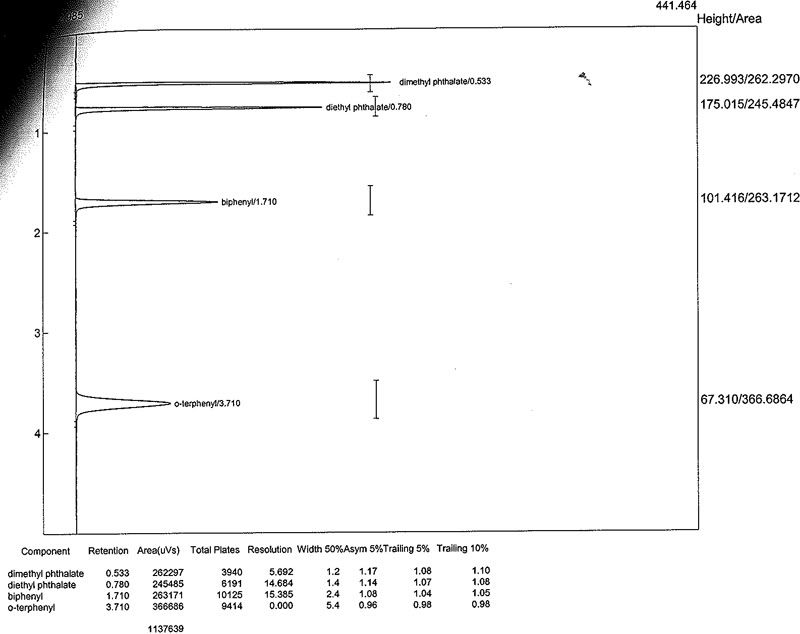

The Problem: The RT is very stable and peak shape is consistent from run to run, but I’m experiencing trouble achieving repeatability in peak height, peak area and plate counts from run to run. I can run a dozen sample injections literally back-to-back and get upwards of 30% variability in these values. The variation between runs usually follows a rough (but variable) ratio for each peak and parameter. I notice however the ratio changes from peak to peak and from run to run. I can discern no clear trend in the data.

It seems like a sample concentration or sample injection quantity issue. The sample itself isn’t degraded or evaporating between runs.

I’ve rebuilt the injection valve and carefully controlled my injection technique (full loop technique, 3x-5x loading). I’ve replaced seals and checkvalves in the pump to minimize the possibility of uneven flow. I tried changing UV detectors and replacing the lamp. I have tried several sample loops from 1.5ul to 15ul and a range of sensitivity settings on the detector. Also I purged the system exhaustively and have achieved a very smooth baseline.

The rest of the details:

Mobile phase: Isocratic 60/40 ACN/H20

Flow: 1.5ml/min

Column: 4.6mm x 50mm Zorbax 1.8um C18

Sample: Isocratic test mix (diethyl & dimethyl phthalate, biphenyl, terphenyl) in meoh

Pump: Waters 590

Detector: Spectra-Physics Spectra100

Injector: Rheodyne 7125

Data Management: SRI Peaksimple

I'll attempt to post a few example chromatograms ASAP. Also I'll try this http://www.lcresources.com/resources/TSWiz/hs380.htm