Page 1 of 2

Baseline rise with temperature

Posted: Mon Jun 30, 2008 11:06 am

by Chris Jones

Hi again everybody!

I have fired up our new Shimadzu GC-2010 using He carrier and no make-up gas (FID). I'm running the same old 80-180 degree program with constant pressure program (or whatever the software dose to regulate it).

Unfortunately we don't have a shiny new column to work with, so I was expecting a bit of baseline rise with temperature. But not 12,000 uV per 100 degree rise. Can a column really be this bad?

Also, what is the ideal air-hydrogen settings on the FID. Currently it's running at 47 ml/min H2, and 480 ml/min for air. Is this normal or ideal for sensitivity and hence baseline stability?

Cheers everyone.

CHRIS

PS Good morning to the Americas! I'm working late on this frigging machine.

Posted: Mon Jun 30, 2008 2:26 pm

by AICMM

Chris,

What is the column? If wax, then maybe toast. If PDMS then not likely. If PDMS and you run another ramp and it goes through the roof, then start looking for leaks in the system. If you are not using make-up and you do have the fitting, is it shut off?

Regarding your flows, the 10:1 is about right for FID's, then manufacturers all set their ideal flows for their own detectors. In the absence of other data I usually run FID's between 35-40 and 350-400 ml/min.

Best regards.

Posted: Mon Jun 30, 2008 9:11 pm

by Rick

Hi

If you work with capillary column, you need make-up gas, like Helium (30ml/min column flow + make-up).....if the problem is not your column, make-up gas is probably the cause of your problem.

Posted: Tue Jul 01, 2008 2:09 am

by Chris Jones

Thanks for your comments folks.

Yes it is a WAX column and it's about 3 years old. It had a hard-ish life in the early days but was plugged for the fallow period.

I will try a temp ramp without the column going into the FID and see if there is a rise. Last time the baseline was all over the place cause of a bad batch of hydrogen. It's a clean baseline at least.

We have never used make-up gas before, so I'd be surprised if this was the cause. However I hear it increases sensitivity? Might look into plumbing a new line into the back.

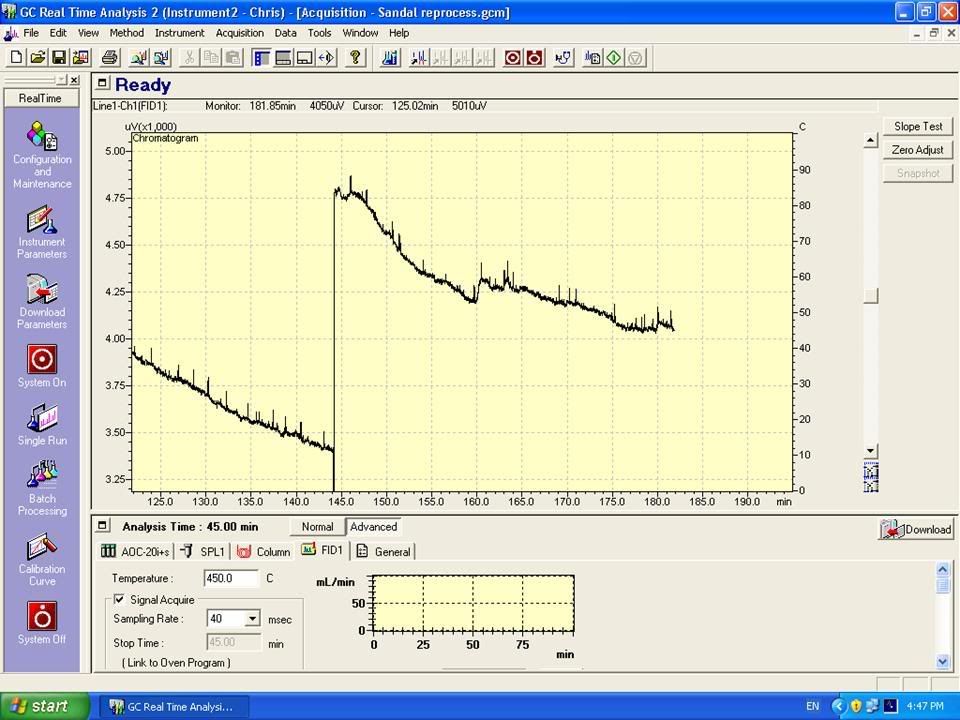

EDIT: Updated diagnostics

Okay, so I disconnected the column and let it vent into the oven. I bunged the column inlet to the FID with a ferrule the stainless steel thing they come with.

No column related problems were expected show up on the FID. I ran an ethanol blank under standard conditions (oven 80-180'C over 20 min) and the exact same baseline rise occured.

Therefore it's clearly not the column's fault. It's got something with the FID. So I changed H2 cyllinders and the same thing happened. SHort of changing the air cyllinder (which I doubt will do anything) I'm at a complete loss.

What now? Is there something with the instrument settings I'm missing here? Does the signal change in response to temperature program without me knowing?

Cheers,

CHRIS

Posted: Wed Jul 02, 2008 7:14 am

by Chris Jones

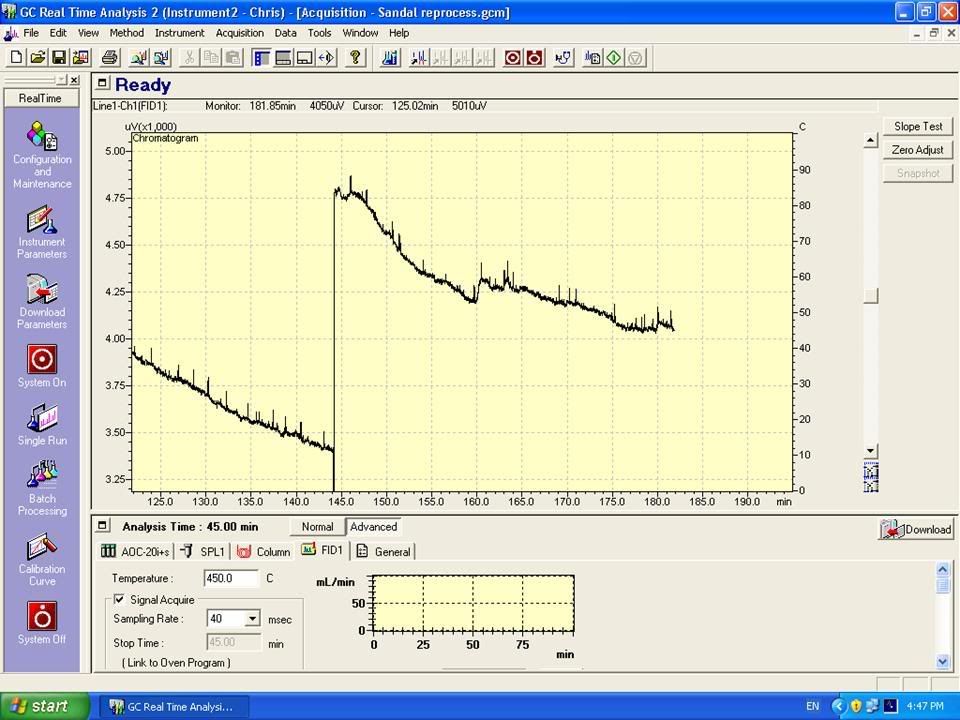

Right, a couple more diagnostics...

We put a branch tube onto the helium carrier and fed this into the make-up inlet. Performance is no different. Oh well, at least now we have a make-up gas.

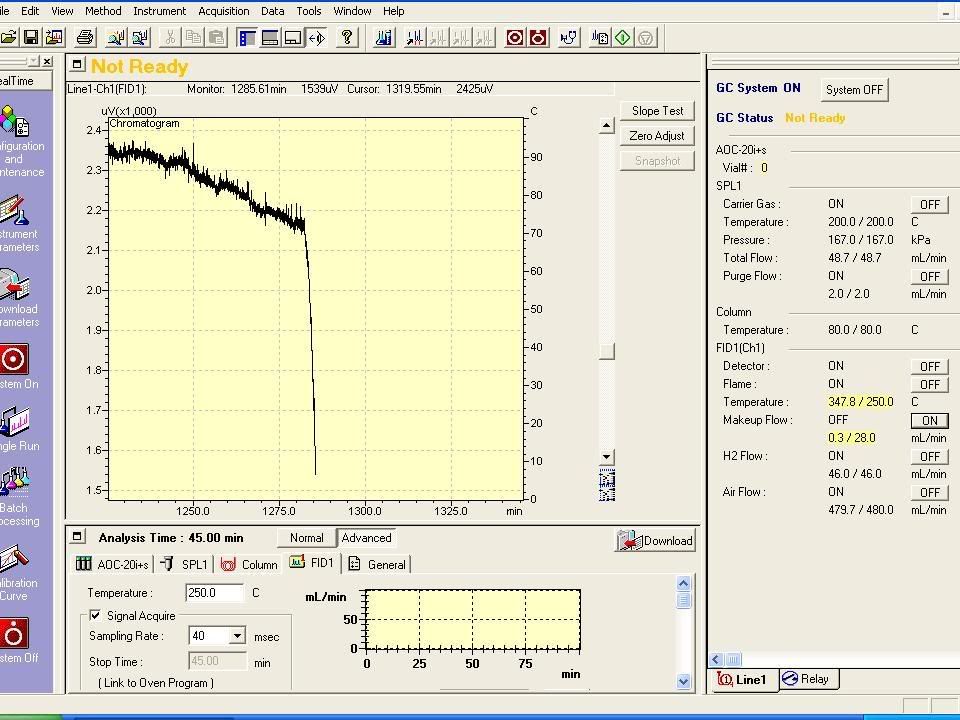

So Greg and I put the FID up to 450'C and have left it to bake for an hour or so now. There was a predictable rise in baseline of 150,000 uV, then a fall, slight rise and a fall again. Right now, it's still on it's way down, but slowly.

The spike and hike was when we set the make-up gas from 28 ml/min to 0.

The next step will be to drop it to 250'C (normal conditions for my analysis of essential oils) and see if it changes again with the oven program.

Watch this space...

Actually now that the GC computer is networked I can check it's progress from home. If I really wanted to

Posted: Wed Jul 02, 2008 10:13 am

by CE Instruments

Are you running in line gas filters ? If so try removing them.

You have proved that FID is reacting to the change in temperature which it should not. FIDs give a signal when something other than the fuel gases burn so heating to 450C should burn off contamination if this is the cause. However it is worth checking that the contamination is not too large to burn off. It is possible to push graphite into the FID from the ferrule so check the flow path is physically clear.

Check the electrical conections to the FID, do you have a dry joint ? Note FIDs do react to being tapped so be very gentle and expect some signal change.

Just my 2c hope it helps

Posted: Wed Jul 02, 2008 2:43 pm

by AICMM

Chris,

Can you actually tell us what the current is from the detector? Not the signal in mV but the actual pA of current being read by the electromer. If you can't give us current, can you translate how your data system is scaling i.e. 1 mV = 1 nA? Reason I ask is this; your chromatogram is showing a lot of spiking and noise so I am thinking that the tremendous signal (150K) is more an issue of scaling than of actual detector noise. Based on what I see, CE's comments about the noisy connections are very applicable.

Also, can you run something at some 10 ug's/mL and post that, perhaps a bit of ethanol in water by headspace or some such.

Best regards.

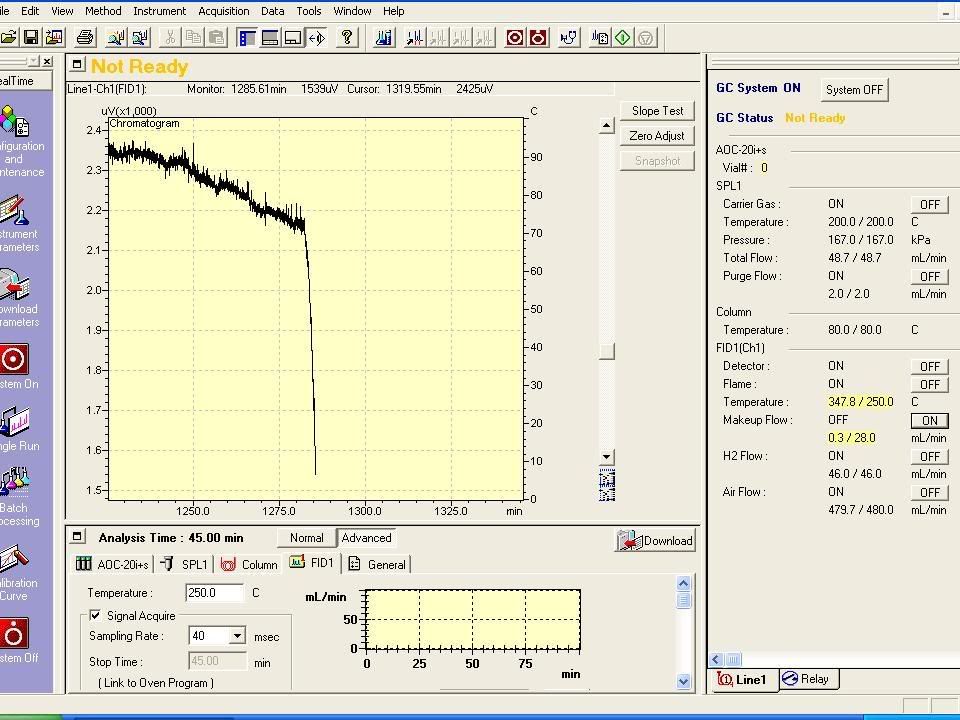

Posted: Thu Jul 03, 2008 3:23 am

by Chris Jones

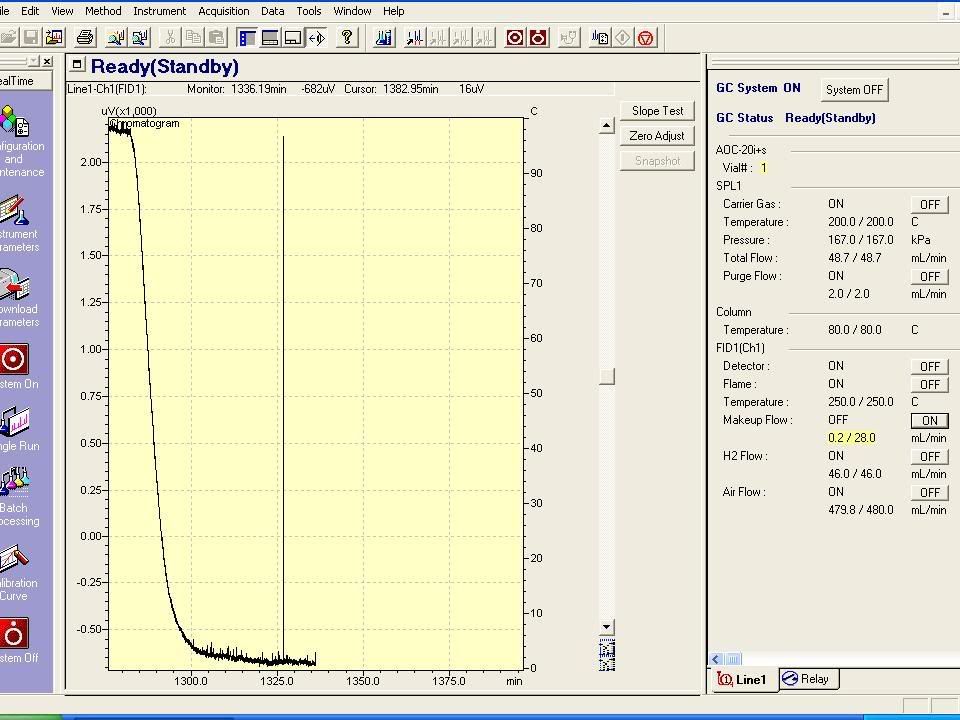

Okay, so here's what happens when the temp was dropped back to 250'C.

It has since started to level off around -600 uV. Once we have a fairly flat baseline I'll go through a normal oven cycle to check what's going on. Remember, it is a brand new GC which has never been used prior.

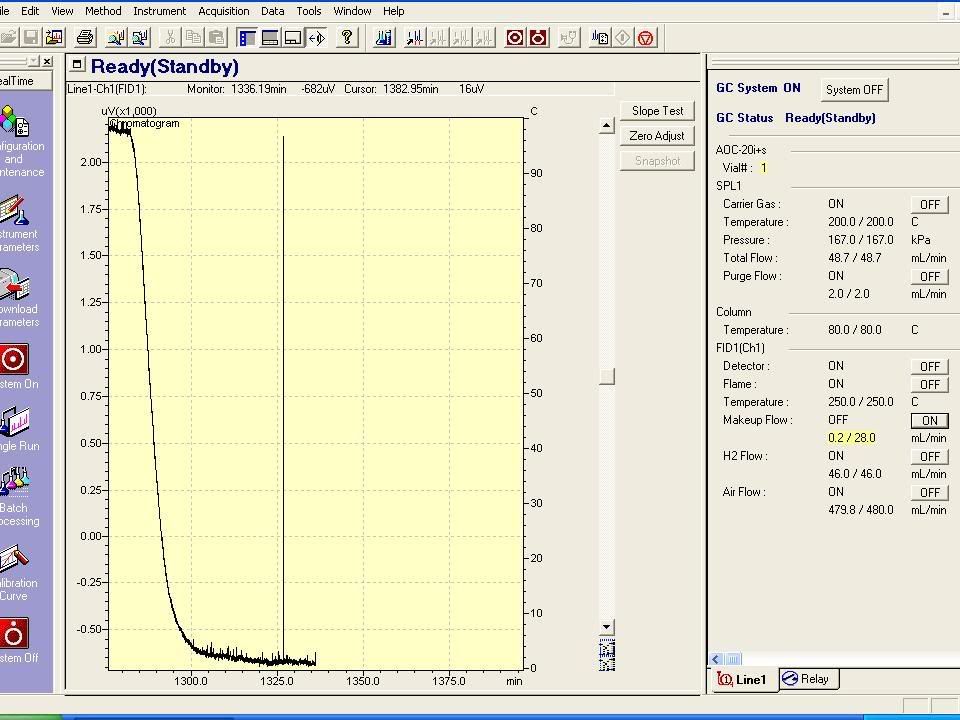

EDIT:

So this is what it looks like just prior to the standard 80-180 oven run.

And this is what happens when you cool it from 450'C back to 250'C, then after a while, the FID was sent back to 450'C.

So it's clearly something to do with the FID. The baseline is exceptionally noisy, but there cannot be anything wrong with it - it's a brand new GC, straight from the box!

The column was an old one, so contamination of the FID may have occurred. There is still a possibility that the H2 and/or cyllinder was badly contaminated, but we'll cross that bridge when we get to it.

CHRIS

PS I have no idea how to work out the current of the FID. How would I do this?

Posted: Thu Jul 03, 2008 9:32 am

by Chris Jones

Sorry to keep on posting like this folks...

I read on the Shimadzu website that another useful diagnostic is to cut the H2 supply and see what happens to the signal. I did this and the signal fell. It leveled out again, with a bumpy baseline fluctuating no more than 2 uV trough to peak. I turned the gases on and ignited the flame again, which led to my familiar unstable baseline with peak to trough differences of about 30 uV. I guess this suggests that it has something to do with the actual burning of material to give a signal, rather than the general sensitivity of the FID.

Anyway, the temperature problem is still there. The local rep will be over to have a look tomorrow afternoon.

Posted: Fri Jul 04, 2008 8:24 am

by CE Instruments

Brand new GC

So it has never worked as you expect ?

Did you have it installed by the engineer and did he get it working fine ?

System is under warranty ? Sounds like time to get the engineer back

Now that shouldn't be...

Posted: Mon Jul 07, 2008 1:58 am

by Chris Jones

Posted: Mon Jul 07, 2008 3:50 am

by chromatographer1

I have seen similar problems due to contamination in gas lines which quickly contaminated the lines in the GC. Usually it means a teardown of all the lines and traps, and cleaning them with replacement if necessary.

A little bit of grease can go a long way. I hope your problem gets resolved quickly.

Good luck,

Rod

Posted: Tue Jul 08, 2008 3:06 am

by AICMM

Chris,

I would still suggest you run something like a little bit of ethanol headspace, perhaps a rum headspace or what not. That allows us to look at signal to noise in a crude cut.

Best regards.

Posted: Tue Jul 08, 2008 3:29 am

by Chris Jones

Sure. I'll see what I can do, but here's the current situation.

I pulled the detector apart to see what was going on. The quartz liner and jet must have been fractured as once the unit was loosened with the socket, the jet fell off! So we replaced it with a new one and let it settle down.

Same results

I ramped the detector up to 350 degrees and sure enough, baseling rose to 120,000 uV. It has since come back down. Busy writing job applications, so I'll have a look in a minute.

Chris

Posted: Wed Jul 09, 2008 6:44 pm

by Ron

Have you shot a sample to see what the signal looks like compared to the baseline noise? You are looking at a very expanded scale here, several of the screen shots show a range of less than 1 millivolt. You heated a detector with a wax column installed to 350C, at least 100c over the upper temperature limit, and the baseline when up to 120 millivolts, or about 12% of the standard 0 to 1 volt range. That is not bad for a column that tends to bleed anyway heated 100C over maximun temperature.

Spiking is usually caused by contamination or bad gases, and I wouldn't trust an old wax column to give a great baseline. If you disregard the spikes, the baseline noise seems to be about 50uV = 0.050mV = 0.000050V, which is not that bad.