-

- Posts: 81

- Joined: Tue Aug 21, 2007 8:02 pm

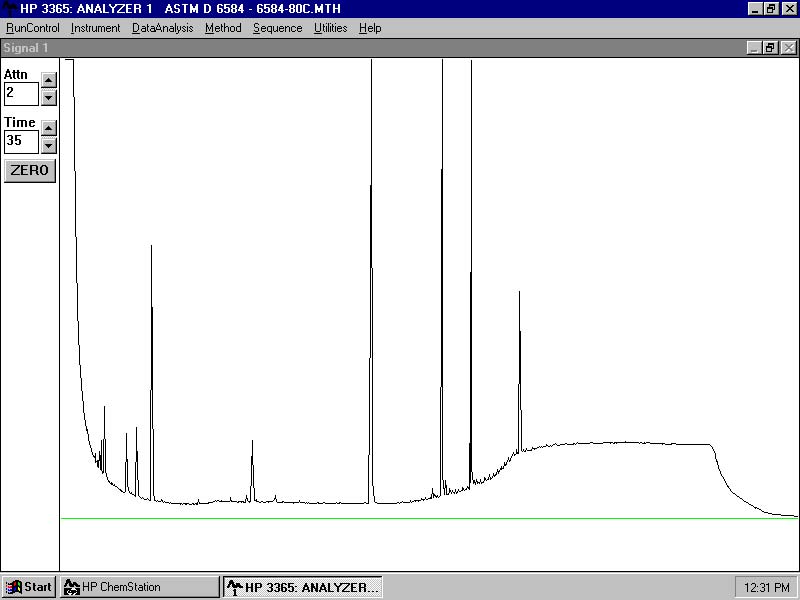

My concern is for what looks to be stationary phase eluting or what I suppose is called column bleed at the termination of the run (380 C according to the ASTM method 6584, held for ten minutes). The column we have is a j&w db-5, part number 123-5711, which my boss has informed me has a max of 350 C. When we purchased it, we were informed that nobody makes a column higher than 350 C.

Although I understand columns will inevitably bleed no matter what temp. they are designed for, I am concerned about the useful life of our column (they are, after all, easily over $300 each).

My questions are:

1) for bd analysis, what kind of life can we expect on a column designed for 350 deg. C, but for which we have to max out our method at 380 deg. C?

2) for bd chromatographers, what kind of column do you use?

3) does the length of the guard column (ours is 5m) have any impact on the life of a column at high temperatures? should we get a longer guard column?

4) should we reduce the holding time for the final temperature ramp (i.e. 380 deg. C at, say 5 minutes instead of 10 minutes)?

5) since we will be primarily using yellow grease, which has a lower carbon count than our triolein standard does, could we get away with lowering the final temperature to, say, 345 deg C?

Thanks