-

- Posts: 48

- Joined: Thu Jun 01, 2017 12:58 pm

There are obviously a "few" obstacles, but the largest one has just been overcome: I now have a column! Drawing quartz capillary myself might be a bit outside the realm of possibility...

Anyway, I'm still getting the design together, but the biggest hurdle right now is column 'plumbing'.

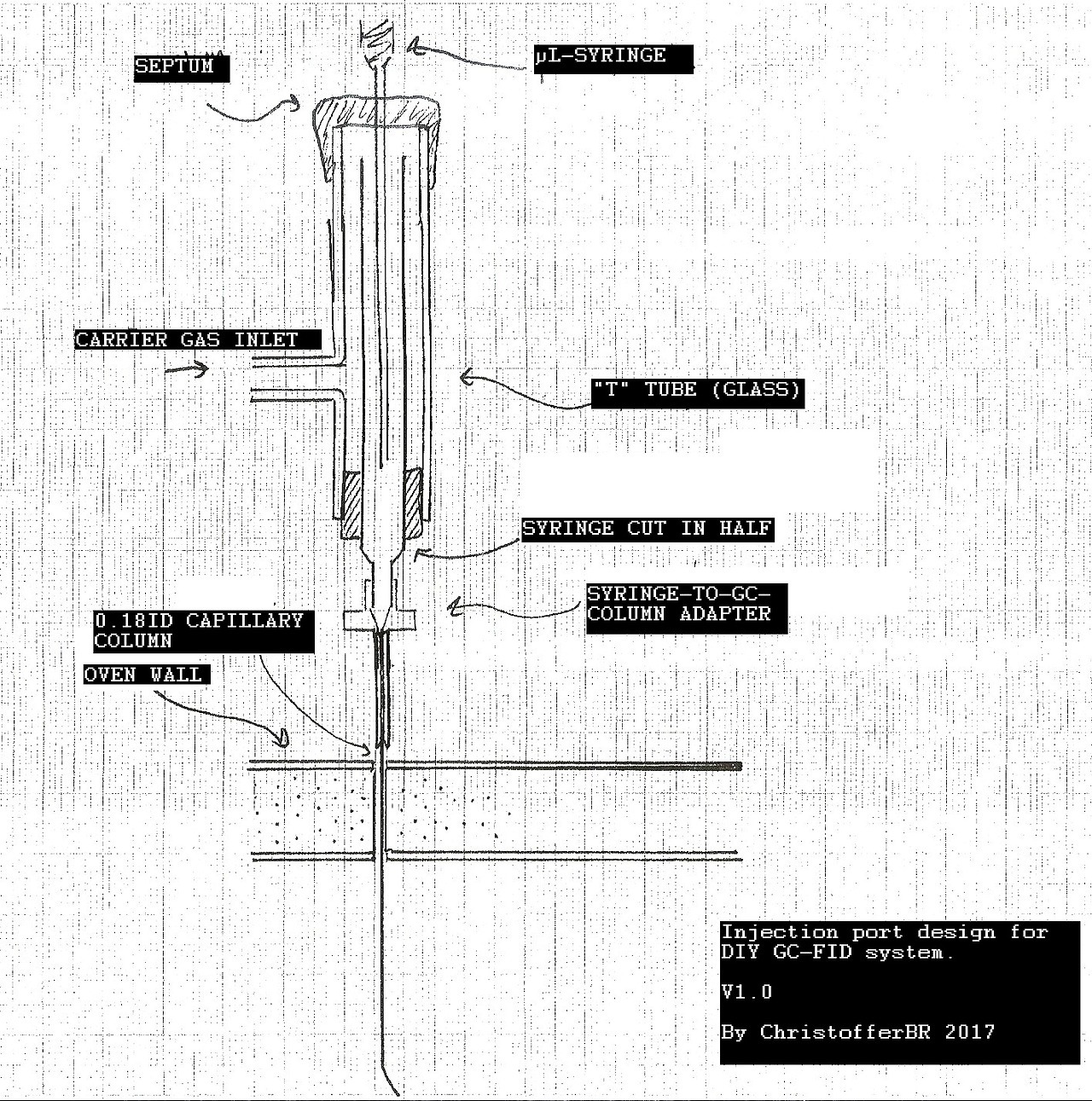

I want to build a simple splitless injector, see image below, but the route I've chosen has the (maybe grave!) problem of having the first ~2-3 cm of column outside the oven. Will this mess things up completely?

Ideally, I'd get a piece of inactive/guard column, feed that through and join them inside the oven, but that adds cost I'd prefer to avoid.

Obviously one major issue is the fact that it's not heated.. But really, my first quest is just to get sample through a system, separation comes second.

I do see Agilent/HP injectors on ebay occasionally, so I'll replace cobbled-together stuff with proffesional spare parts when they come around cheaply.

The other issues that I've sortof figured out, but not made yet are:

-Oven from a kitchen 'mini oven' - with computer control/temp feedback

-FID built after 1960's early GC articles, output to pen plotter

-Carrier gas N or He, don't want a H2 cylinder in my home!

-FID Hydrogen supply perhaps from small electrolysis rig?

Thanks for your interest!