-

- Posts: 2

- Joined: Mon Feb 06, 2017 5:05 pm

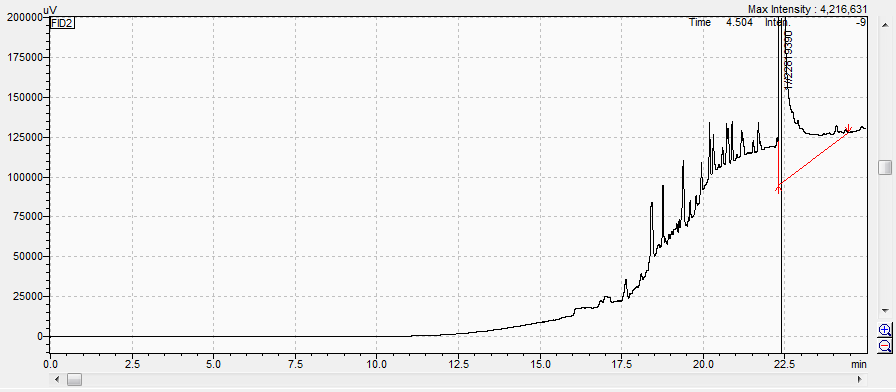

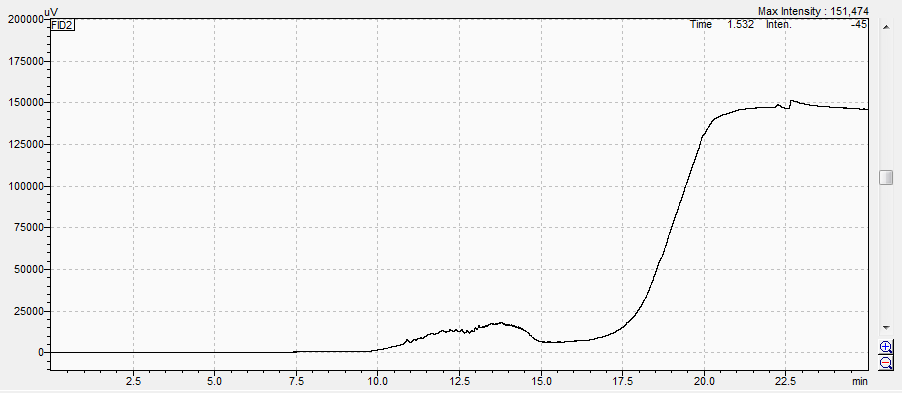

Any subsequent runs yield a chromatogram with a hump in the 10-15 minute area, as shown in the following picture:

Since then I removed the glass liner I attempted to clean and replaced with a brand new one. I was careful to keep it clean during handling(disposable gloves, used tweezers when able to) and I even replaced the septum at the same time. However, I am still getting this peak on subsequent runs after the first run after the chromatograph has been running overnight.

From what I have read I think I may have contaminated part of the column with something that doesn't elute on the first run but, when the column is heated up, vaporizes and shows up in all subsequent runs. Any ideas on what may have happened or ways to remedy this, such as cutting a small section off of the beginning of the column to eliminate this contaminated section?

I am using the following:

GC: Shimadzu GC2010 plus

column: Restek Rtx-200 Crossbond trifluoropropylmethyl polysiloxane 30 meter, 0.53 mmID, 0.5 µm df

UHP Helium carrier gas

I've ever only used SPME fiber for analyzing BTEX in this column and injector

Thanks