-

- Posts: 9

- Joined: Wed May 25, 2011 9:48 pm

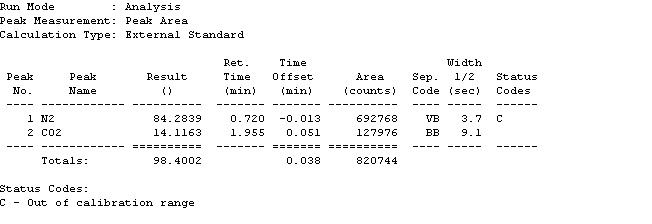

I am pulling gas samples directly from a tank that is a blend of N2/CO2 at ratio of 60/40 (analyzed by supplier). I monitor the GC inlet pressure and keep it fixed via a regulator. I also monitor the GC outlet flowrate and keep it fixed with a rotometer.

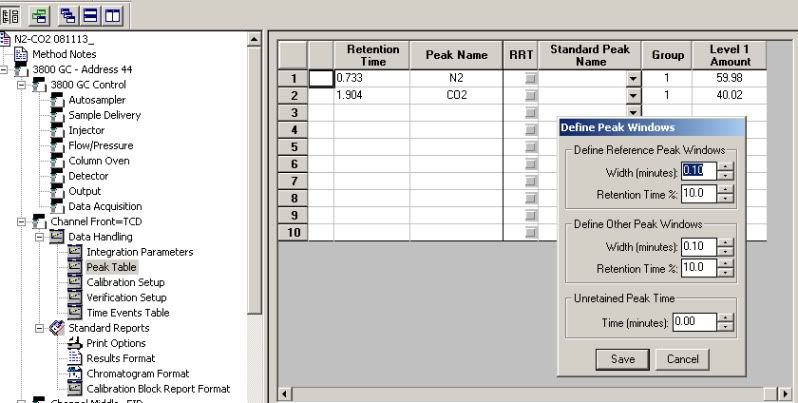

I analyzed the blend several times to get consistent retention times: t_N2 = 0.737 and t_CO2 = 1.911.

Now I disconnect the line at the tank of N2/CO2 and connect it to a different blend of N2/CO2 at 86/14. I fix the inlet pressure and outlet flow to the same exact values as the previous blend. However, this time I consistently get t_N2 = 0.725 and t_CO2 = 1.955.

These differences are significant enough that if I calibrate the method using one blend, it cannot recognize the other blend as being N2 and CO2. Furthermore, if I connect pure CO2 I get yet another retention time.

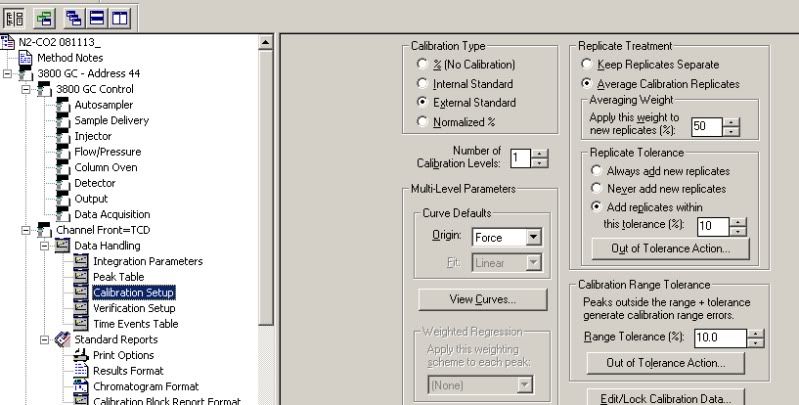

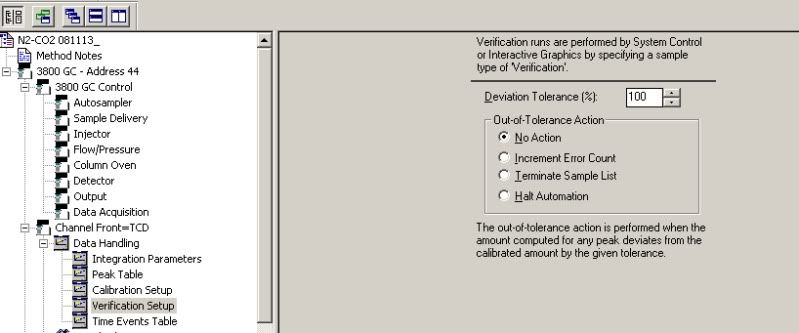

I know that there is so much info that goes into a method, that you probably need a lot more info to pinpoint the problem, but maybe you guys can give me some places to start since I really don't know much about this. I am under the impression though that I should be able to calibrate the method without having to know ahead of time what the mixture composition is. That would just be silly.

Thanks for reading

EDIT: How the heck did I end up in Data SYstems forum? Sorry