-

- Posts: 43

- Joined: Wed Jan 04, 2006 6:47 am

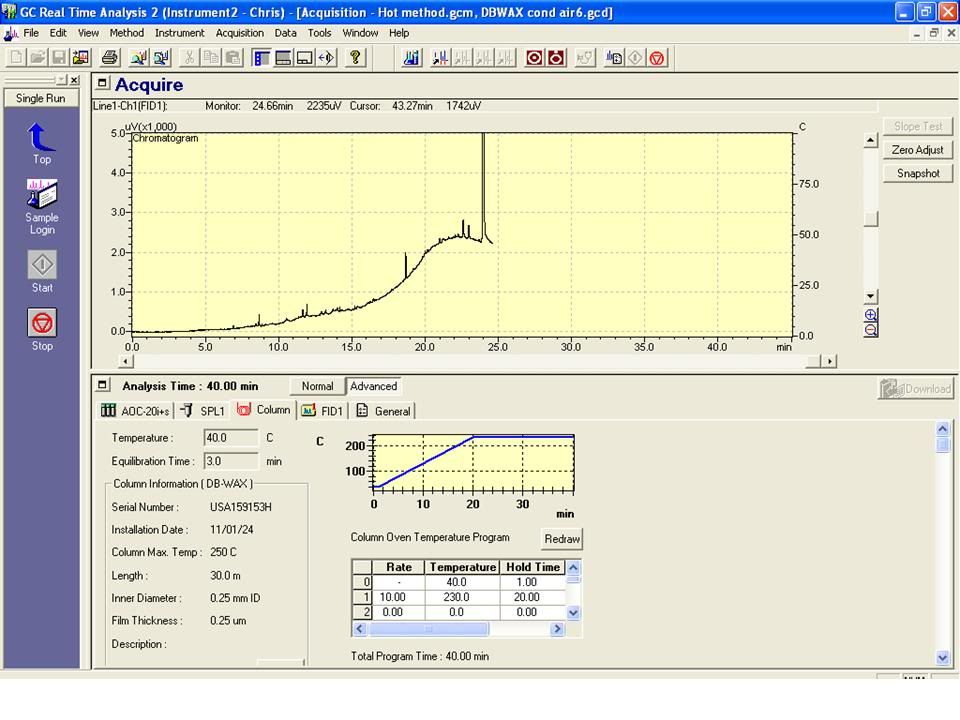

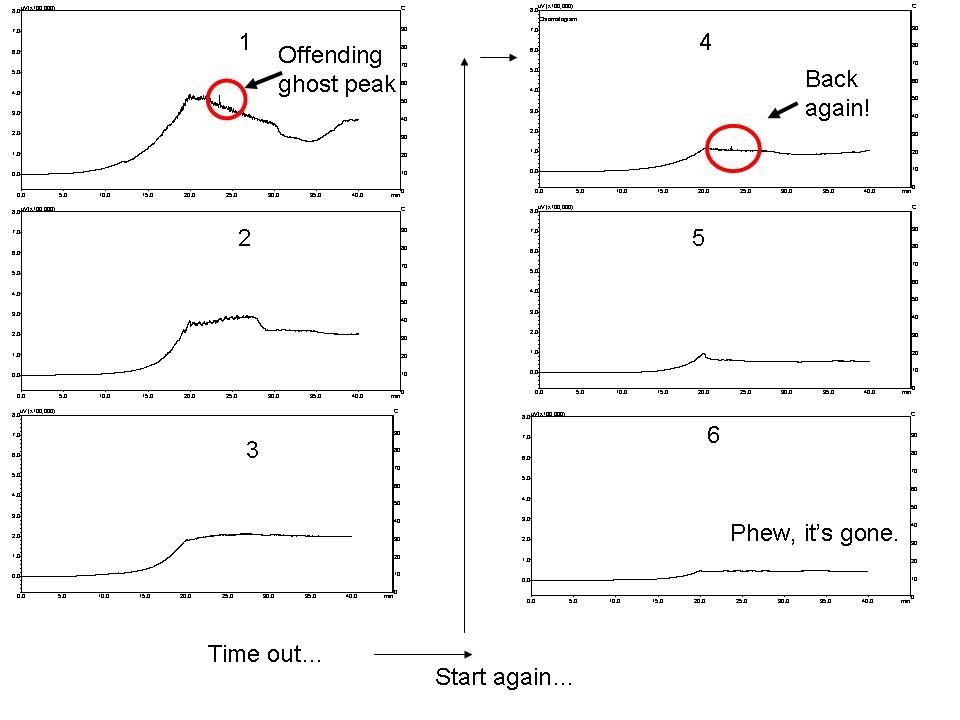

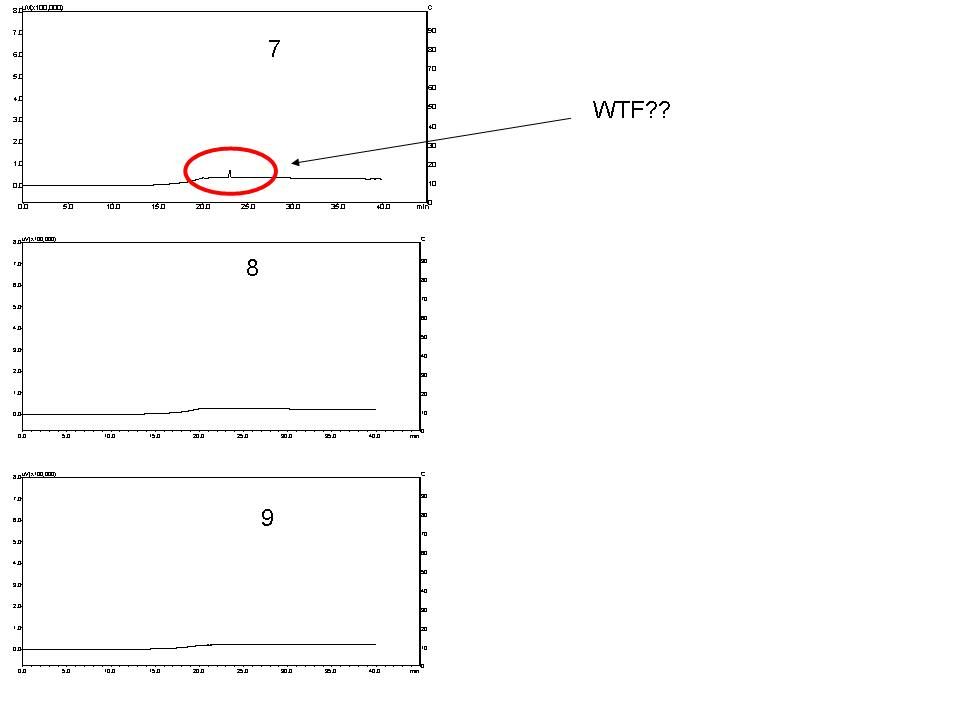

Been a long while since I consulted the brains trust that is ChromForum. Mostly been busy with other stuff, but I have recently fired up the Shimadzu GC2010 with FID and I've been trying to get it into a fairly normal baseline. New DB-WAX column (30 m) installed, new splitless liner, new septa. I am just conditioning the column so I inject an air sample, 40 degree oven for 10 mins, then up to 200 for 10 min then 230 for 20 mins.

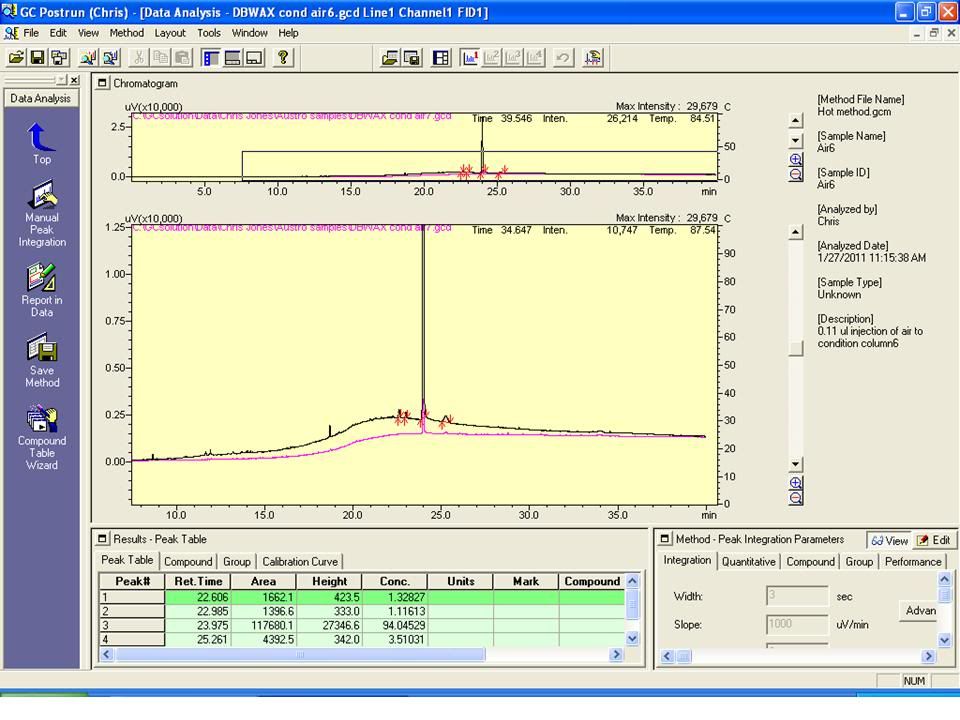

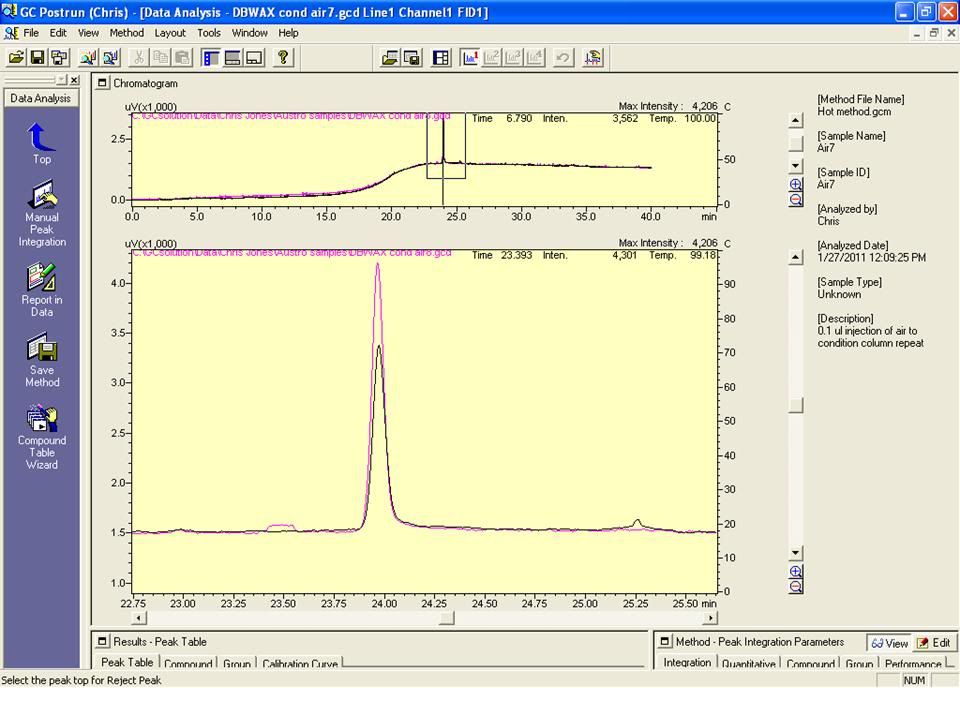

I am constantly getting a peak at about 35 minutes. I have seen this with different columns, different gas bottles, different solvents. Injecting air gives the same peak. I have concluded that the septa might be coated in a waxy compound, of say C15-C20. New septa makes no difference, so I'm confused. Any ideas?

Cheers guys,

CHRIS

To really screw things up, you need a machine.