-

- Posts: 4

- Joined: Sat Nov 13, 2010 1:42 am

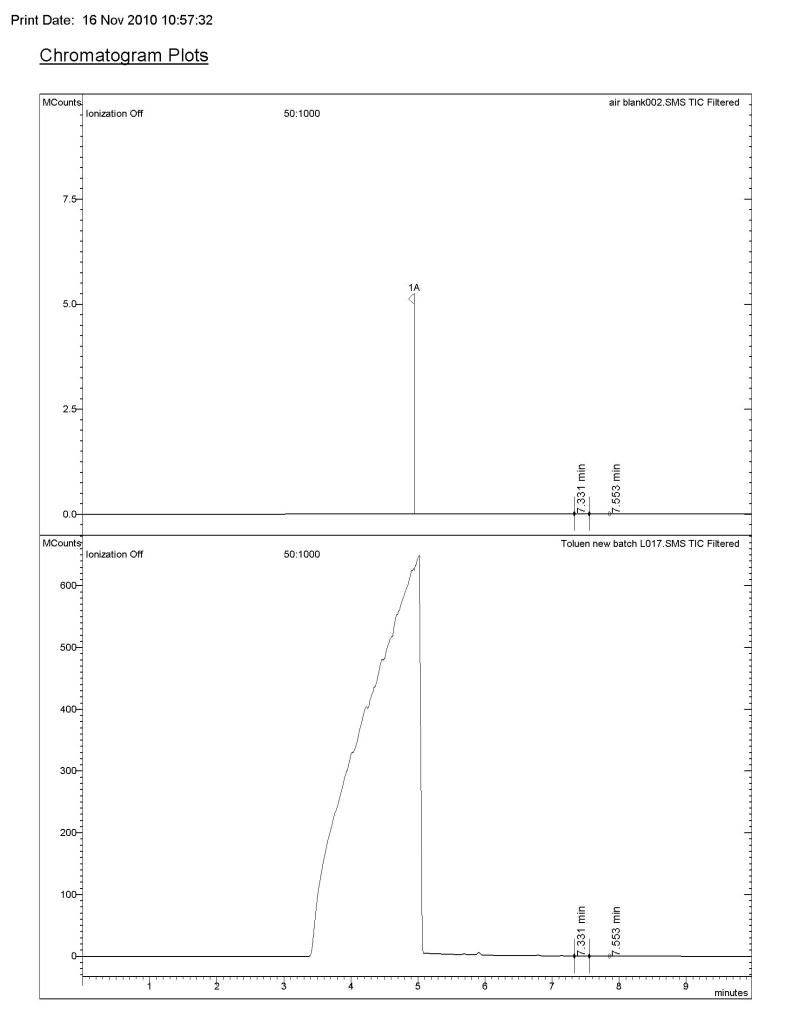

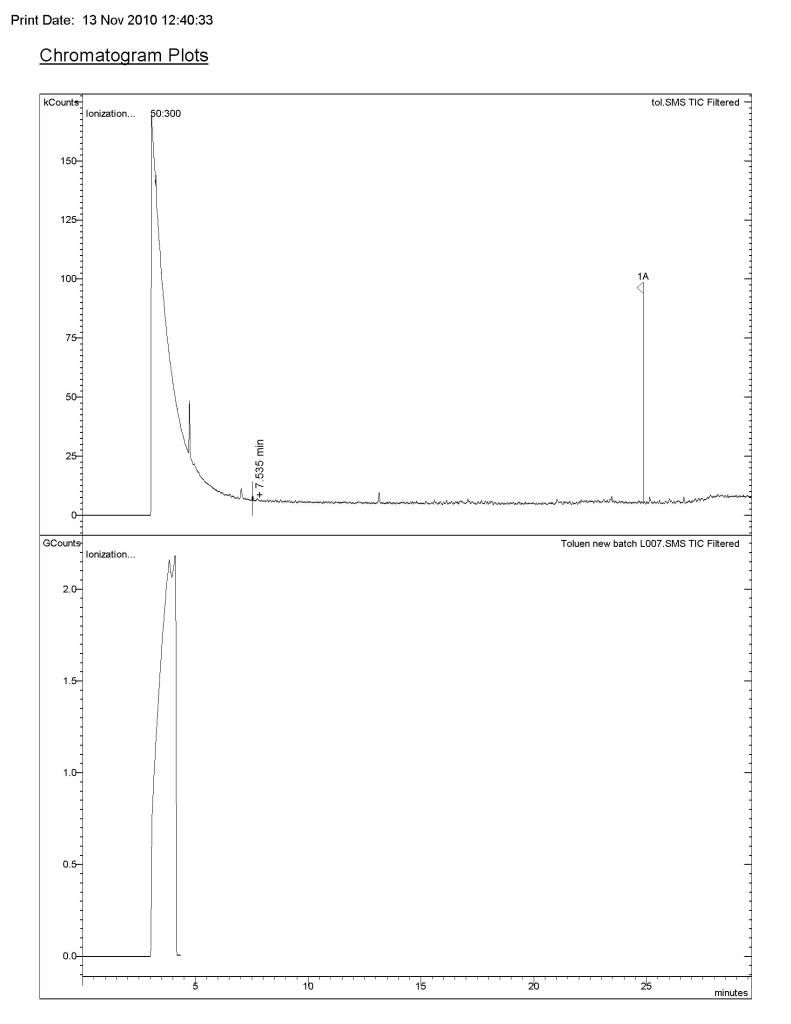

I was hoping someone might be able to point me in the right direction in terms of troubleshooting. I have a strange peak (bottom of picture) which I am getting after the stringe bent and it was replaced. Normally the Toluene solvent peak is sort of okay as per the top part of the picture but for some reason it is being a bit temperemental at the moment.

I have trimmed the Column, baked the oven, changed the septa and liner, checked ferrules and the likes, the only thing left i can think of is to replace the column but i would LOVE to avoid that if possible.

Is there anything I may be missing that may cause such a crappy and intense peak?

[/img]

[/img]