by

MrSem25 » Wed Nov 03, 2021 10:19 am

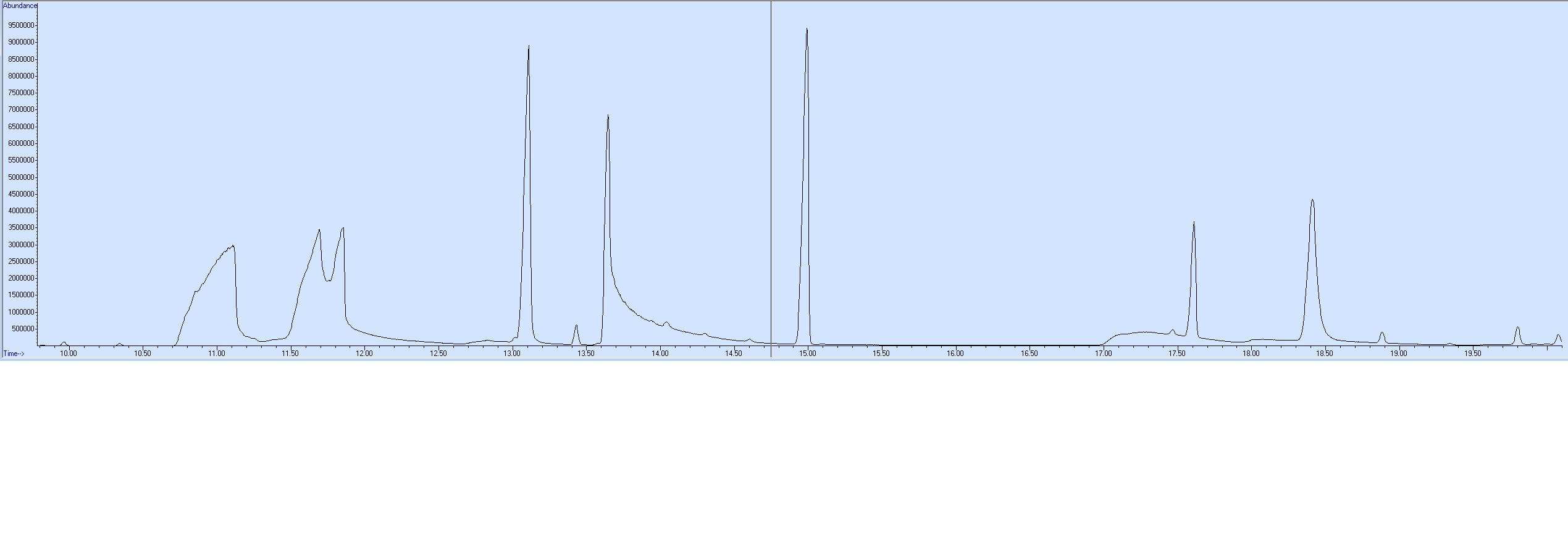

If changing the column corrected the problem then it returned after running more samples, then it sounds like something in the samples is contaminating the inlet or head of the column.

Does removing a loop of the column change the peak shapes?

For some tests that I do I have to do inlet/column maintenance daily, which includes replacing the inlet liner, cleaning the inlet with a solvent soaked swab, and removing about 100mm of column. If it requires removing that much column every day I use a guard column in front of the main analytical column to extend the life of the analytical column. Depending on the test, I can get by with not removing any of the analytical column before the 1m of guard column is used up but sometimes after a few trimmings of the guard column I have to remove it and take off 100mm of analytical column then replace the guard column.

Are you injecting with split injection or splitless injection?

What type of injection port liner are you using?

What is the injection port temperature?

What volume of sample are you injecting?

More information will help us diagnose the problem.

Thank you for your answer.

I do not give samples with high viscosity. Since I work in a Polar-Nonpolar way, I think I should have experienced the same problem with Polar.

What is the protection column?

I am using split injection and 0.5 µL injection.

On October 18th I solved the problem by doing the following:

-I changed the column.

-I checked the EPC.

-I cleaned the EM Volt with IPA.

-I cleaned the ION Source.

-I renewed the Septa inside Merlin.

-I renewed the inlet line.

After doing these steps, my problem was fixed.