Page 2 of 4

Re: GC/MS Large volume injection

Posted: Thu Oct 06, 2016 5:55 pm

by sav

The only problem I am running into now is with tailing of Pentachlorophenol and Benzidine.

...

But if you install a Uniliner the pentachlorophenol returns.

...

I am beginning to suspect our Methylene Chloride has something to do with it.

I didn't work with these analytes, but once i had some "magic chemical purity effect" when impurities (introduced by "bad" HCL which peoples used in samples) induced degradation of analyte (hard peak tailing). I used Agilent UI series column, Restek Sky liner without wool and different sample preparation protocols and it's not helped (only HCL with appropriate purity helped).

So, try to check "solvent effect" with MTBE (better), AcOEt etc. Also, you can try Sky liners (Restek).

Re: GC/MS Large volume injection

Posted: Thu Oct 06, 2016 6:06 pm

by James_Ball

The only problem I am running into now is with tailing of Pentachlorophenol and Benzidine.

...

But if you install a Uniliner the pentachlorophenol returns.

...

I am beginning to suspect our Methylene Chloride has something to do with it.

I didn't work with these analytes, but once i had some "magic chemical purity effect" when impurities (introduced by "bad" HCL which peoples used in samples) induced degradation of analyte (hard peak tailing). I used Agilent UI series column, Restek Sky liner without wool and different sample preparation protocols and it's not helped (only HCL with appropriate purity helped).

So, try to check "solvent effect" with MTBE (better), AcOEt etc. Also, you can try Sky liners (Restek).

Our semivolatiles analyst has been using the Sky focus liners with wool in the center and has the same problem. That is one of the reasons I am beginning to suspect our solvents, since that liner should not degrade so quickly. Once before when Fisher sent us a lot of MeCl that had the wrong stabilizer in it we lost most of our surrogate and spike recoveries. Once we figured it out things went back to normal. In this work, cheaper is not usually better overall.

Re: GC/MS Large volume injection

Posted: Fri Oct 07, 2016 9:43 pm

by James_Ball

I experimented with every liner type we had and still had breakdown and severely tailing pentachlorophenol, so, last night I let the system run on hydrogen to clean things out a little. This morning I made a shot with hydrogen as the carrier and the peaks were tailing less, but of course there was tons of hydrocarbon peaks at the beginning from where the hydrogen is scrubbing out the system. Next I began reducing the injection speed.

Went from 1500ul/min to 750ul/min and it improved a little. Dropped to 500ul/min and looked even better. Dropped to 250ul/min and tailing is even better. Went all the way to 100ul/min injection speed, which takes 6 seconds to inject the 10ul and peaks look very good, tailing factor in the 1.7-3 range. I thought I had it figured out, so I switch back to helium. Same parameters, I injected sample, now DFTPP peak height dropped from 4,000,000 to 600,000 and pentachlorophenol is a ski slope blob just before DFTPP. DDT peak went from 4,000,000 height on hydrogen down to 150,000 on helium. Going to switch back to hydrogen and see if the sensitivity and peak shapes come back. I wonder if the phenols just need that much extra linear velocity to move through the column with good peak shapes? But it still doesn't explain where the DDT went.

edit

The above was run using a new liner that is the 5.2mm ID silcosteel liner from Restek with single gooseneck. Trying that to see if the larger volume also helps.

Switched back to hydrogen and I have a little more response but the tail is still there for pentachlorophenol and DDT still has a small peak. Going to let it bake overnight with hydrogen again and see what happens.

Re: GC/MS Large volume injection

Posted: Sat Oct 08, 2016 1:50 pm

by sav

James_Ball, Interesting. I don't experimented with different gases in CRS LVI. I think in your case hydrogen "deactivates" some adsorption sites (i also observed this effect with some "active" compounds in GC-FID when switched from He to H2). Looks like you have some active adsorption sites in your system or may be your solvent have some impurities which activates/creates these sites (column and retention gap with press-fit connector also must be in the list of suspicious). But DDT/DFTPP? Is peak shape of DDT/DFTPP a good? (only peak area decreased when you switched to He)

I also experimented with low injection speed (< 1000 ul/min) and had decrease of recovery (analytes without "active" groups in the range 1000 - 3000 RI). My design of CSR LVI was very simple (Helium as gas; 100 ul syringe) - single tapered splitless liner with enough (!!!) quantity of deactivated glass wool at the bottom of liner, 0.53 mm X 5 m IP deactivated retention gap and injection speed in the range 6000 - 60000 ul/min. But glass wool ("deactivation degree" is not matter) is a bad thing when you're dealing with "active" compounds especially with CRS LVI when residence time of analyte in injector is relatively high.

Re: GC/MS Large volume injection

Posted: Mon Oct 10, 2016 1:34 pm

by Peter Apps

The Grobs did a lot of work on large volume injection with various configurations of inlet and retention gaps several years ago - 1980 - 2000 or so at a guess. they had some quite elaborate set ups to overcome the instability of solvent films in smooth-walled tubes and a lot of what they did is painfully vulnerable to small changes in conditions, but it might be worth a look on Google Scholar.

Peter

Re: GC/MS Large volume injection

Posted: Mon Oct 10, 2016 3:14 pm

by GOM

Hi

I went on a LVI injection course many years ago at the biannual International Symposium on Capillary Chromatography (ISCC) at Riva del Garda, Italy

One of the presenters was Koni Grob.

I think that it was 1996 if that helps to narrow down your literature search

During that time I first met Ray Perkins of what is now Anatune and purchased an Atas Optic LV injector from him, which I used successfully.

check out

http://www.glsciences.eu/html/lvi-injection.html

Ray would be a good person to contact with his knowledge in this area and probably have some good literature references and helpful comments

Regards

Ralph

Re: GC/MS Large volume injection

Posted: Mon Oct 10, 2016 8:23 pm

by James_Ball

Thanks everyone! I will start looking into these suggestions.

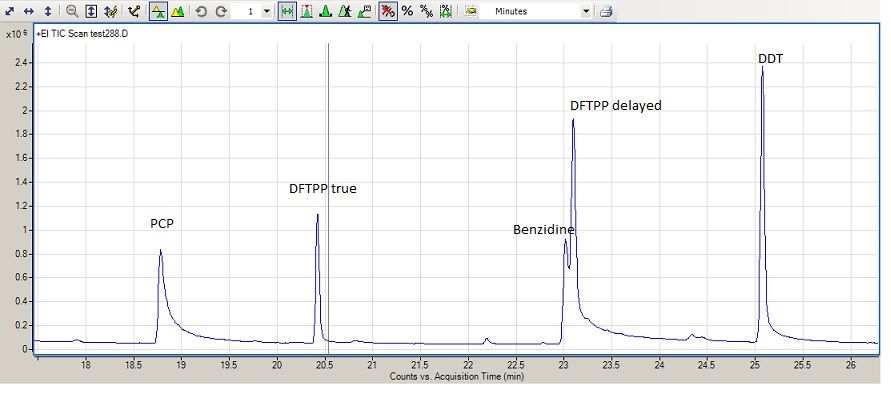

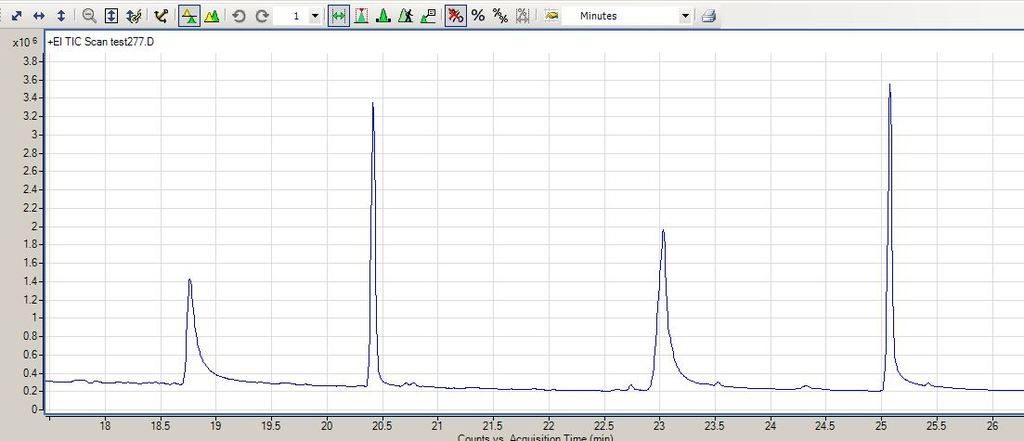

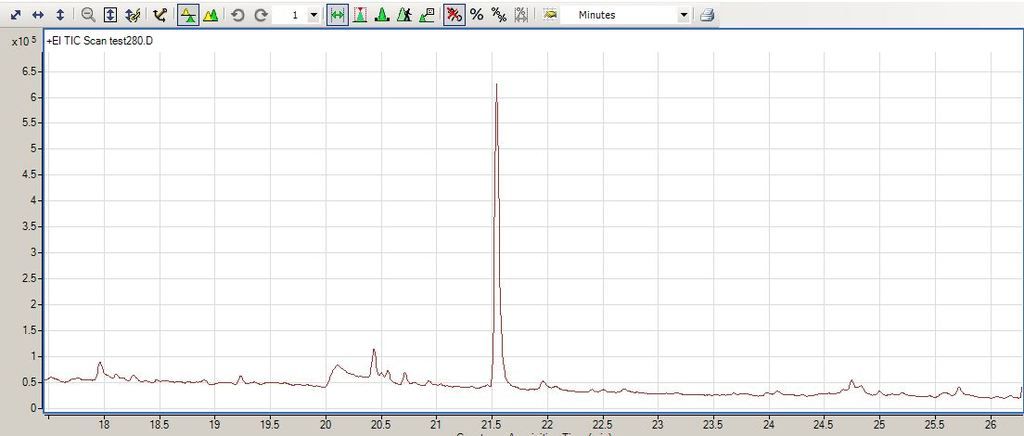

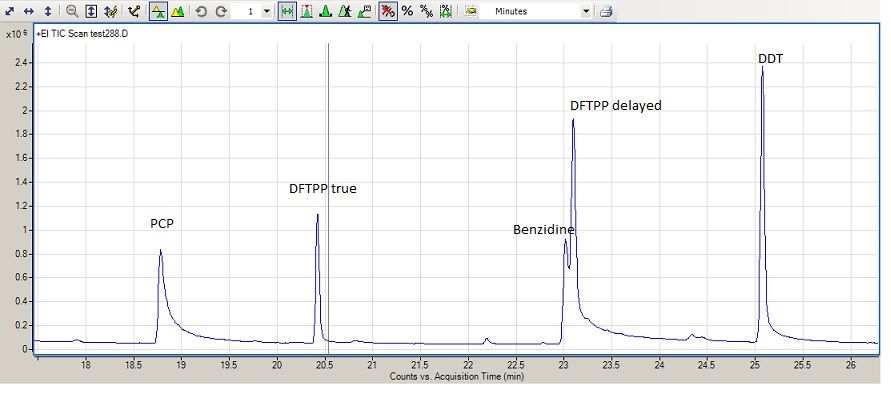

I ended up letting the system bake with hydrogen over the weekend. This morning I did an injection with hydrogen carrier and got a broad peak for pentachlorophenol, and after a few injections it is now a decent peak again. Now the strange thing. The DFTPP peak was not where it was supposed to be. The first injection it was co-eluting with benzidine. The second injection there was a small peak at the proper retention time just after pentachlorophenol and still a larger peak inside the benzidine peak. Two more injections and the peak at the correct retention time is larger but still there are two peaks. Oddly both peaks are nearly perfect in shape.

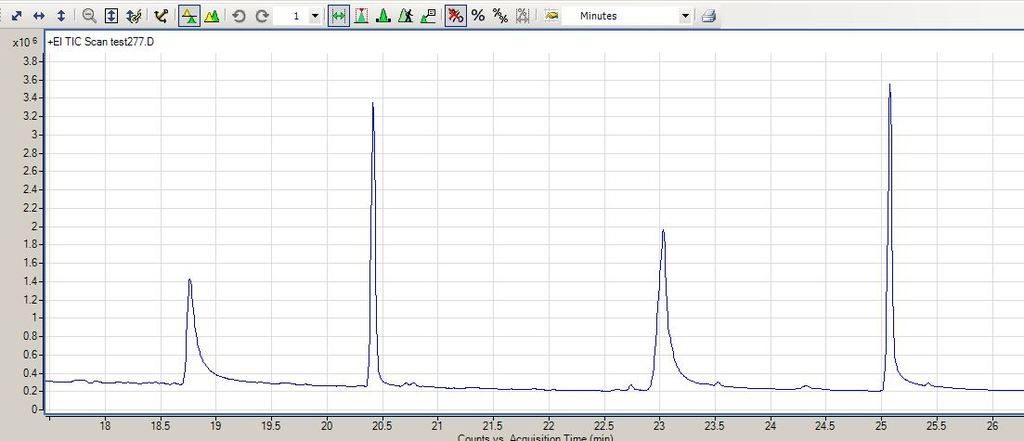

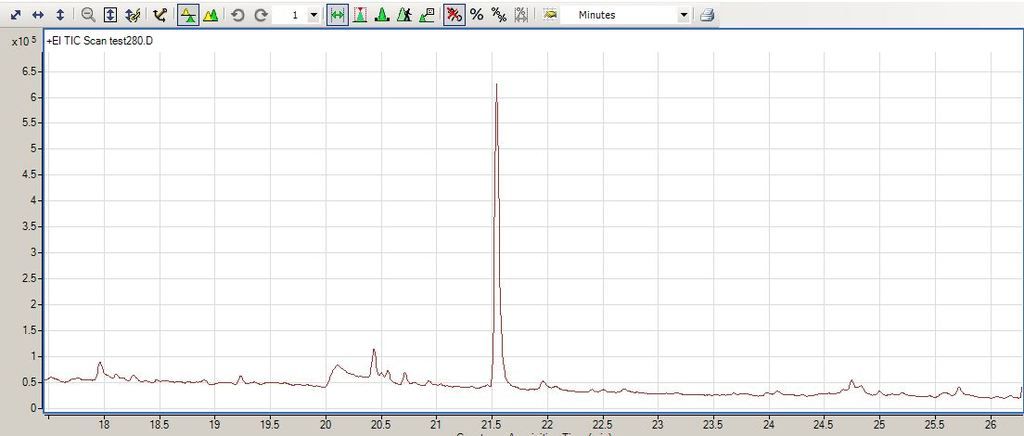

Current shot after baking over the weekend and making 4 injections.

Last good injection before switching back to helium for one injection.

The single shot made on helium after getting it cleaned up on hydrogen.

The retention time for DFTPP is a little later on the helium and it is the only peak that actually shows up. I am still at a loss why switching to helium for a single injection messed things up so much. When I was developing on helium originally the PCP and benzidine were very poor but DDT was good. DDT is there in the helium injection but is just off screen and the height is only about 100k.

Re: GC/MS Large volume injection

Posted: Tue Oct 11, 2016 5:05 am

by Peter Apps

Hi James

The DFPTT jumping around may be because some of it sits in the liner until it gets hot enough to shift while some of it gets onto the column with the solvent and starts moving immediately _ I saw a similar thing working on packed bed solvent effect inlets back on the 1980s.

The hydrogen helium deactivation activation is bizarre. My packed bed inlets were deactivated with silicon and were very very inert (better than the columns) and I was using hydrogen all the time (with an FID).

Peter

Re: GC/MS Large volume injection

Posted: Tue Oct 11, 2016 3:51 pm

by James_Ball

Hi James

The DFPTT jumping around may be because some of it sits in the liner until it gets hot enough to shift while some of it gets onto the column with the solvent and starts moving immediately _ I saw a similar thing working on packed bed solvent effect inlets back on the 1980s.

The hydrogen helium deactivation activation is bizarre. My packed bed inlets were deactivated with silicon and were very very inert (better than the columns) and I was using hydrogen all the time (with an FID).

Peter

Would this happen with the injection port at 250C during injection?

I started with hydrogen because our guy doing GC/ECD pesticides said he never has breakdown on pentachlorophenol and he is running hydrogen carrier. The normal semivolatiles analyst has been having trouble with this for a few years now. I had not been looking at pentachlorophenol on the 7000QQQ because I had been using it for either volatiles or other special projects like canabinoids or seed extracts. Now I have two research projects, developing LVI methods and solving the breakdown problem. At least I am never bored ))

Re: GC/MS Large volume injection

Posted: Tue Oct 11, 2016 7:14 pm

by James_Ball

Ugh, I feel like a first day GC operator now. Figured out the problem with the split DFTPP and the peak shapes. I decided to clean the injection port again and when I removed the retention gap from the inlet I saw the problem. Apparently when I tightened the column nut the column slipped down and was just barely caught by the ferrule.

The end of the column being below the inner surface of the gold seal was causing the dead volume that made the peak split, and I assume the large injection volume was what caused such a large shift in the times.

There is some garbage in the first couple injections so far, but the peak shapes are back to where they were before switching to helium. Since I reseated the column after the helium injection I still don't know what caused the total loss of PCP with helium, but one less variable to worry about now.

Re: GC/MS Large volume injection

Posted: Tue Oct 11, 2016 9:10 pm

by Peter Apps

Hi James

The DFPTT jumping around may be because some of it sits in the liner until it gets hot enough to shift while some of it gets onto the column with the solvent and starts moving immediately _ I saw a similar thing working on packed bed solvent effect inlets back on the 1980s.

The hydrogen helium deactivation activation is bizarre. My packed bed inlets were deactivated with silicon and were very very inert (better than the columns) and I was using hydrogen all the time (with an FID).

Peter

Would this happen with the injection port at 250C during injection?

I started with hydrogen because our guy doing GC/ECD pesticides said he never has breakdown on pentachlorophenol and he is running hydrogen carrier. The normal semivolatiles analyst has been having trouble with this for a few years now. I had not been looking at pentachlorophenol on the 7000QQQ because I had been using it for either volatiles or other special projects like canabinoids or seed extracts. Now I have two research projects, developing LVI methods and solving the breakdown problem. At least I am never bored ))

Very likely the displaced column was the problem, but you get quite dramatic cooling when you rapidly evaporate something very volatile from a thermal insulator like glass wool - I think that there was an attempt to exploit this by putting a very thin walled liner inside an ordinary liner - possibly a Riva paper from a few years ago.

I wonder what would happen if you ran hydrogen during standby, and then switched to helium just before injection ??

Peter

Re: GC/MS Large volume injection

Posted: Tue Oct 11, 2016 11:35 pm

by sav

James_Ball, Thanks for pics and info. Yes,

it happens

About PCB and benzidine:

1. Switch to H2 from He

or

2. Derivatization (TMS derivatives etc.;

http://link.springer.com/article/10.136 ... 005-0692-7 ;

https://www.ncbi.nlm.nih.gov/pubmed/18479692 )

or

3. Optimization of chromatographic system for reducing active sites (another column/phase at the first place)

Re: GC/MS Large volume injection

Posted: Wed Oct 12, 2016 6:49 pm

by James_Ball

I plan on going with option #1 since this is an EPA method and pretty much throws out option #2. Though running methylated standards from the herbicide group made very beautiful peak shapes for the pentachlorophenol, but when that is in a mix with over 100 other compounds, methylating would cause mass confusion as to what is what.

Re: GC/MS Large volume injection

Posted: Wed Oct 12, 2016 7:04 pm

by James_Ball

Hi James

The DFPTT jumping around may be because some of it sits in the liner until it gets hot enough to shift while some of it gets onto the column with the solvent and starts moving immediately _ I saw a similar thing working on packed bed solvent effect inlets back on the 1980s.

The hydrogen helium deactivation activation is bizarre. My packed bed inlets were deactivated with silicon and were very very inert (better than the columns) and I was using hydrogen all the time (with an FID).

Peter

Would this happen with the injection port at 250C during injection?

I started with hydrogen because our guy doing GC/ECD pesticides said he never has breakdown on pentachlorophenol and he is running hydrogen carrier. The normal semivolatiles analyst has been having trouble with this for a few years now. I had not been looking at pentachlorophenol on the 7000QQQ because I had been using it for either volatiles or other special projects like canabinoids or seed extracts. Now I have two research projects, developing LVI methods and solving the breakdown problem. At least I am never bored ))

Very likely the displaced column was the problem, but you get quite dramatic cooling when you rapidly evaporate something very volatile from a thermal insulator like glass wool - I think that there was an attempt to exploit this by putting a very thin walled liner inside an ordinary liner - possibly a Riva paper from a few years ago.

I wonder what would happen if you ran hydrogen during standby, and then switched to helium just before injection ??

Peter

Right now I am using the Restek 5.2mmID Silcosteel single gooseneck liner, which is very thin walled to give more volume for evaporation. Currently there is no glass wool, every time I attempt to add the glass wool I get complete breakdown of the pentachlorophenol. Instead of the Siltek deactivated borosilicate wool I have been using, I am going to take some plain glass wool and silanize it in the liner and see if that works better.

Re: GC/MS Large volume injection

Posted: Wed Oct 12, 2016 7:52 pm

by Peter Apps

Hi James

If there is no glass wool and the liner is metal you will not get temporary cooling, but a 10 ul flash evaporation is a lot of vapour at 250C and even if it does get pushed into the megabore retention gap by the resulting pressure pulse and condensed I wonder if you are not getting flashback also with the PCP sticking to something upstream of the liner ?.

Peter