-

- Posts: 103

- Joined: Sat Mar 12, 2011 4:02 pm

- Location: Moscow, Russia

James_Ball wrote:

Right now I am using the Restek 5.2mmID Silcosteel single gooseneck liner, which is very thin walled to give more volume for evaporation.

Instead of the Siltek deactivated borosilicate wool I have been using, I am going to take some plain glass wool and silanize it in the liner and see if that works better.

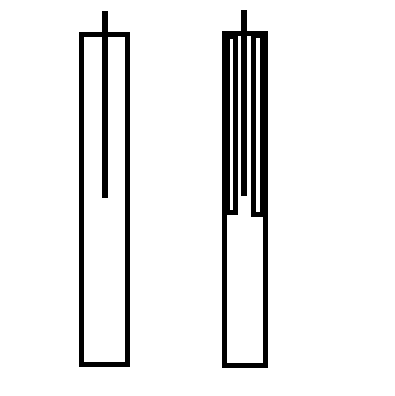

IMHO, Silcosteel isn't best choice as well as manually silinized glass wool in this case (its not help). You need just good deactivated single gooseneck glass liner with carbofrit (Restek Sky liner etc. with carbofrit). The carbofrit works much better than any super best deactivated glass wool when you dealing with active analytes but, honestly, i don't know how it will work in CSR LVI. Also doble gooseneck is better than single gooseneck in CSR LVI.